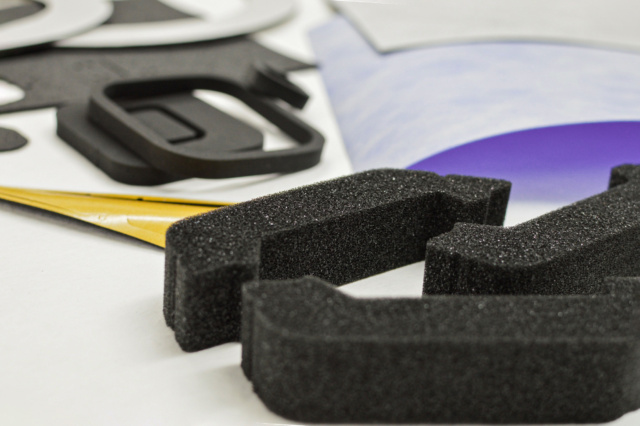

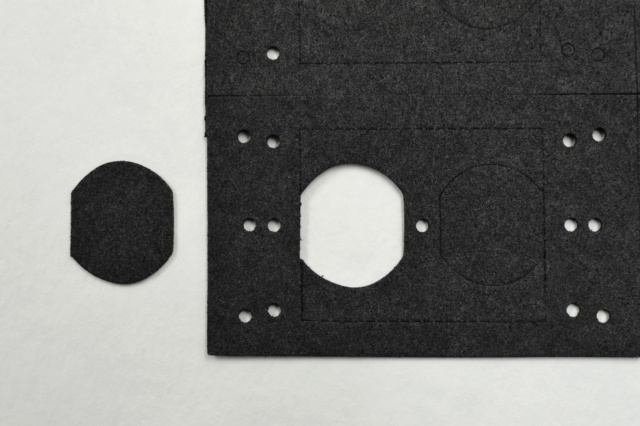

Die Cutting

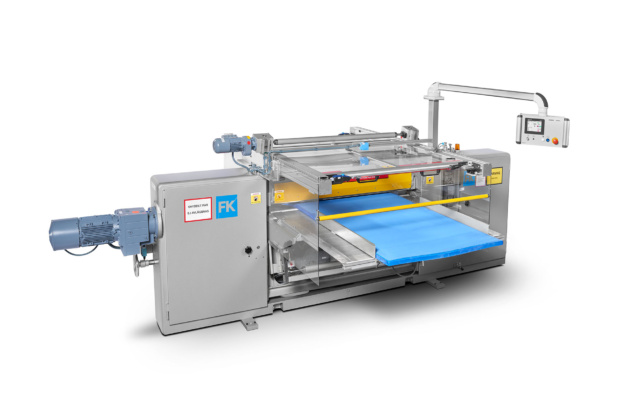

Machinery presses a steel rule die into the flexible material, cutting it into a specific shape. We use both fixed and traveling cutting head machines.

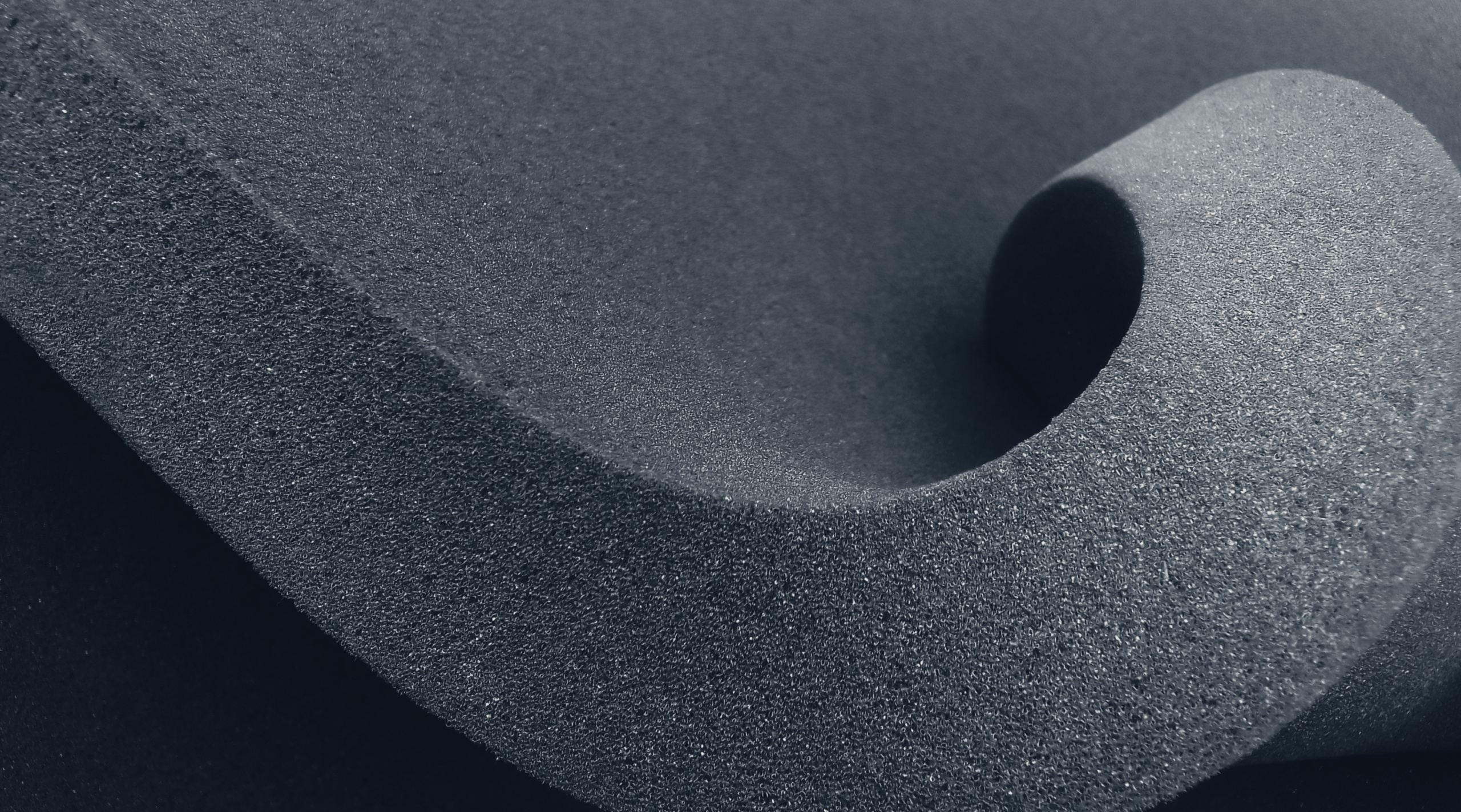

We convert flexible materials into unique parts through innovative manufacturing processes.

Our team of seasoned manufacturing personnel will evaluate the specific requirements for the part that you need and develop a solution that will leave you satisfied.

When it comes to manufacturing, we never shy away from a challenge. We strive to play a critical role in the completion of your project.

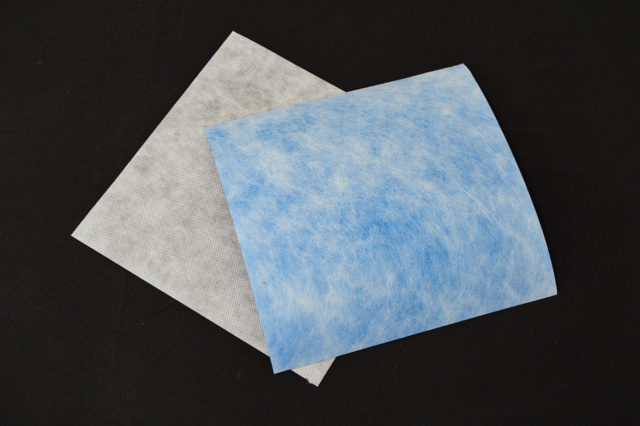

We work with a wide variety of materials to produce your finished part. Each material has its own unique characteristics that allow it to perform better than other materials in certain applications. Some of these characteristics include the material’s density, color, tensile strength, water absorption capabilities, compression-deflection rating and compression-set rating. We will use materials that meet your requirements and perform to your satisfaction.

Our materials are sourced from the most reputable suppliers in the industry. We conduct material inspections throughout our manufacturing processes to confirm that the materials meet our high standards for quality. We assure you that your finished product will only contain high quality materials that have passed careful inspection.

Our 120,000 square foot manufacturing facility is equipped with a robust collection of foam converting machinery. Your materials may pass through two or three converting processes before reaching their final form. Each converting process is controlled by highly skilled machine operators.

Our team of quality control engineers and maintenance specialists ensure that all of our equipment remains in its optimal condition so that we can provide consistent reliable quality.

Machinery presses a steel rule die into the flexible material, cutting it into a specific shape. We use both fixed and traveling cutting head machines.

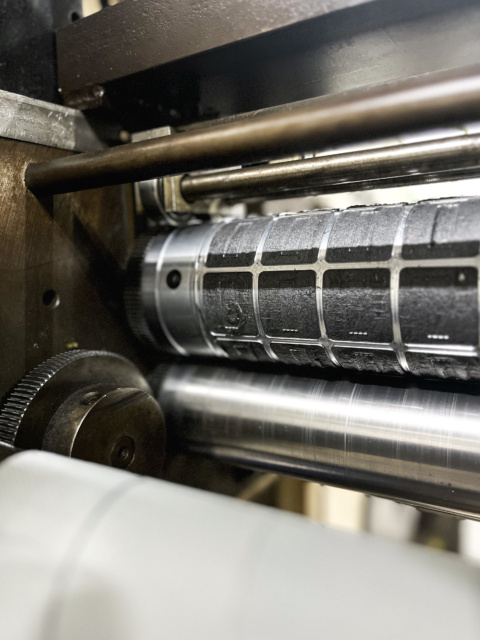

Machinery with multiple stations allows laminating and cutting multiple layers of materials. Cylindrical steel dies rotate over the material to cut precise shapes at high speeds.

CAD-CAM machinery controls a saw blade to cut precise shapes out of a material. We have equipment for both vertical CNC saw cutting and horizontal CNC saw cutting.

Large rolls of material are unwound and rewound through a machine to create smaller rolls. Our rewinding machines are fully automated, rewinding at speeds up to 450 fps.

Machinery slices or shaves the material in layers at a specific thickness. We can skive materials down to 1 mm thick.

Machinery bonds layers of foam to other pieces of foam, films, fabrics and adhesives. Processes such as wide web adhesive lamination can give a piece of foam an adhesive backing.

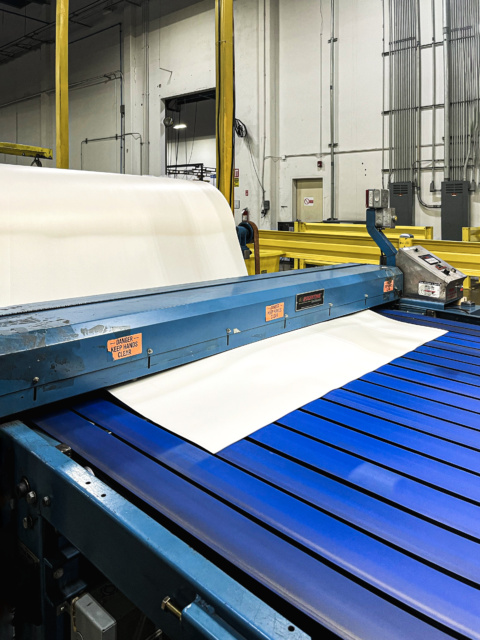

A roll of flexible material is unwound and cut into specific lengths.

Our custom parts can be found in a diverse mix of applications, from tail light gaskets in luxury cars to high performance acoustic underlayments in flooring systems. Our foam parts can be used to reduce sound transfer, limit moisture transfer, serve as product packaging and much more.

What we do